Description:

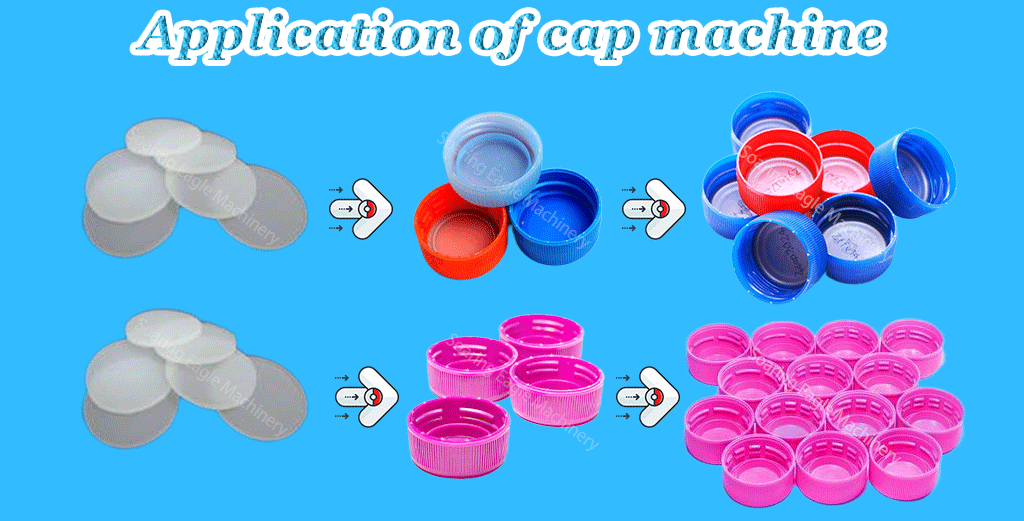

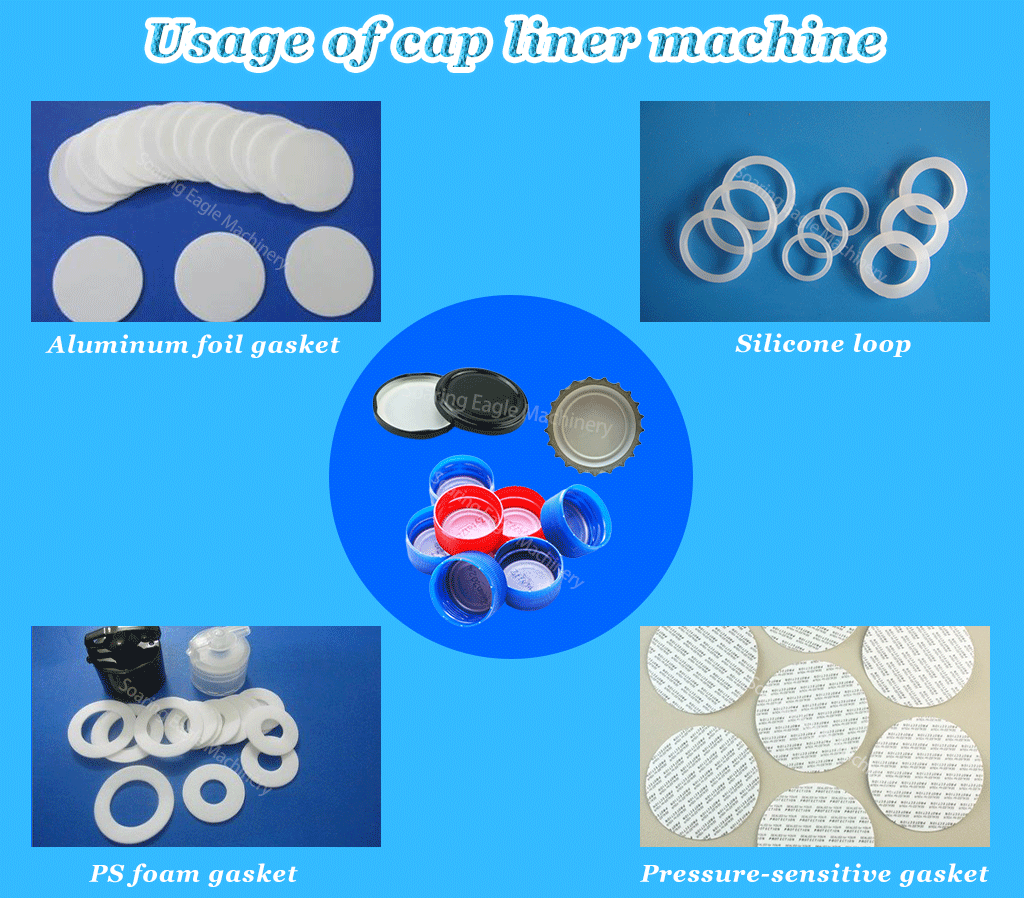

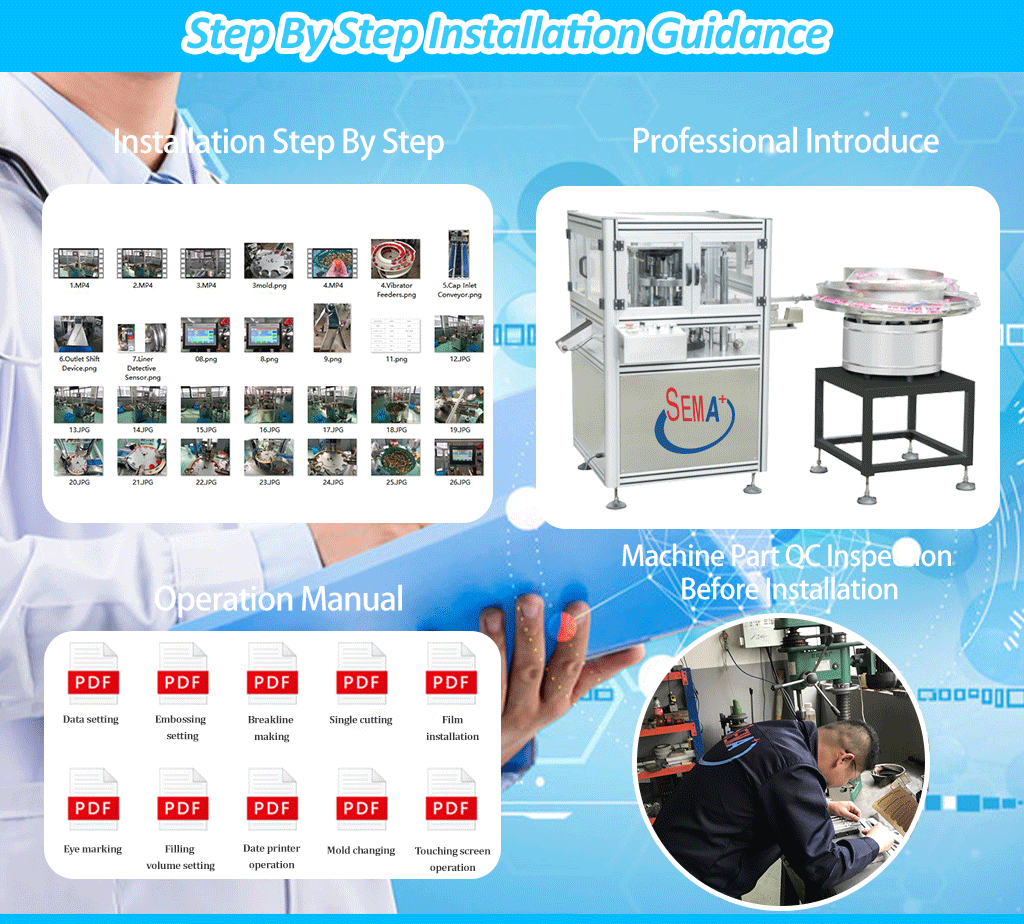

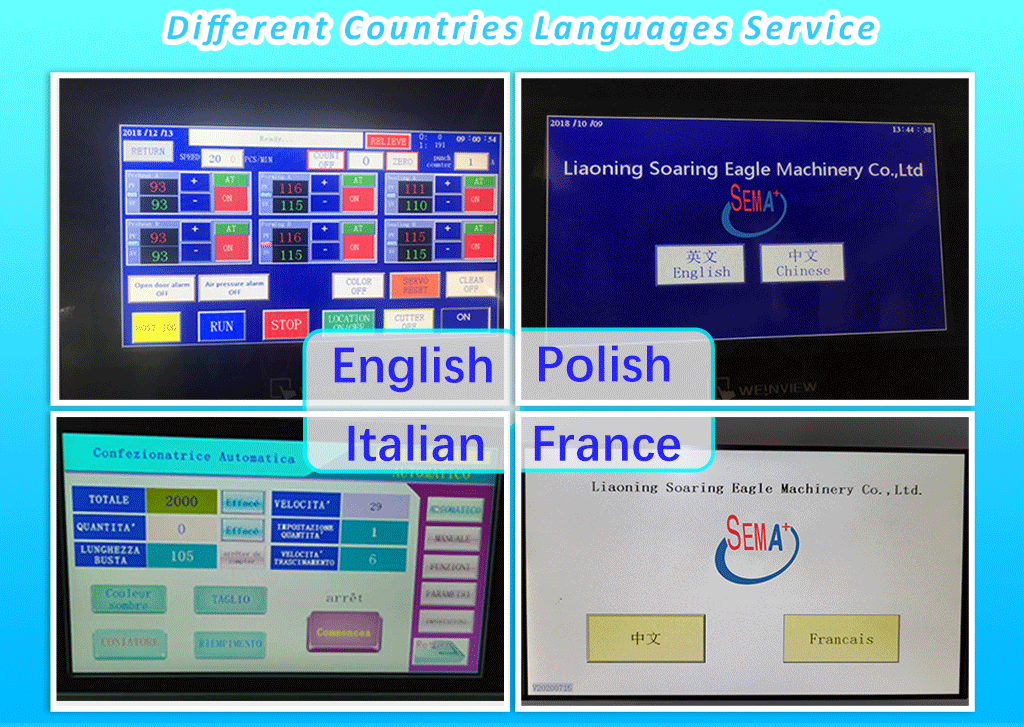

The Twist cap wadding capping lining machine could automatically put the shim into lids instead of manual. There are four primary advantages I would like to mention. First of all, the shim is much flatter. What’s more, the speed is much more quicker. Last but not least, the product safety could be provided. The whole machine uses PLC control, so the operation is easier. It could also counting the number. This machine could also exclude the wrong lids.

Technical parameter:

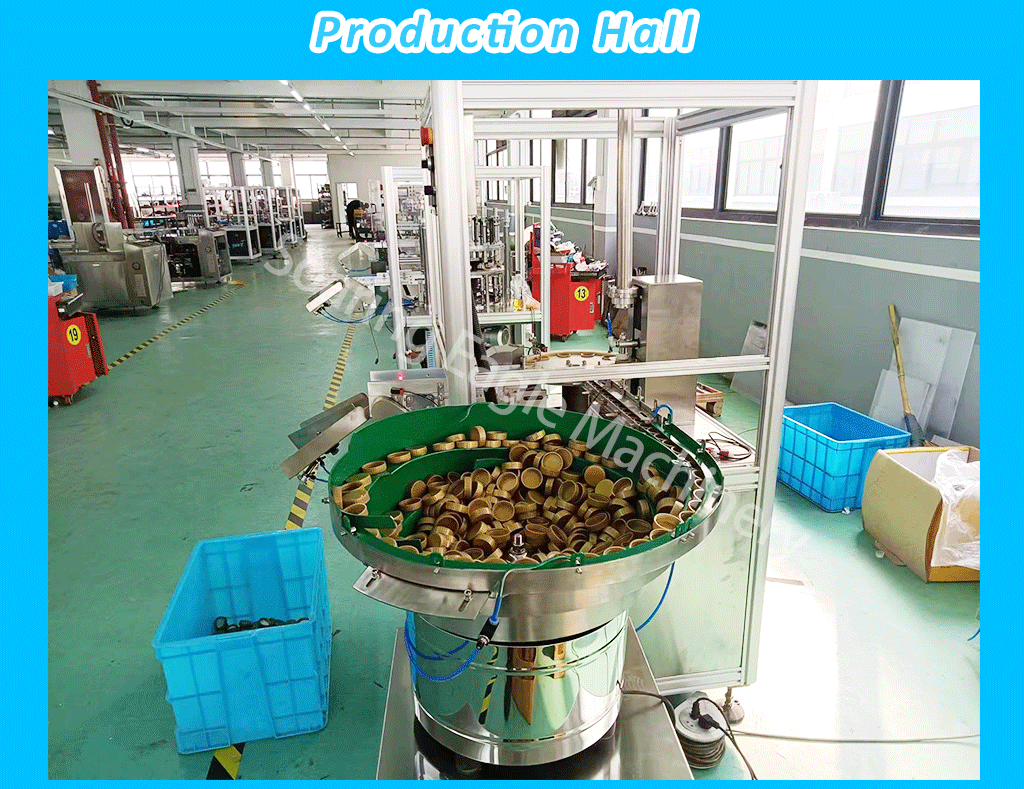

1.Application:This machine is an ideal cap liner inserting machine which is widely applied in cap factories, liner factories, pharmaceutical factories, food products factories, daily chemical factories, packing factories, etc..this model is designed for the bigger bottle cap.

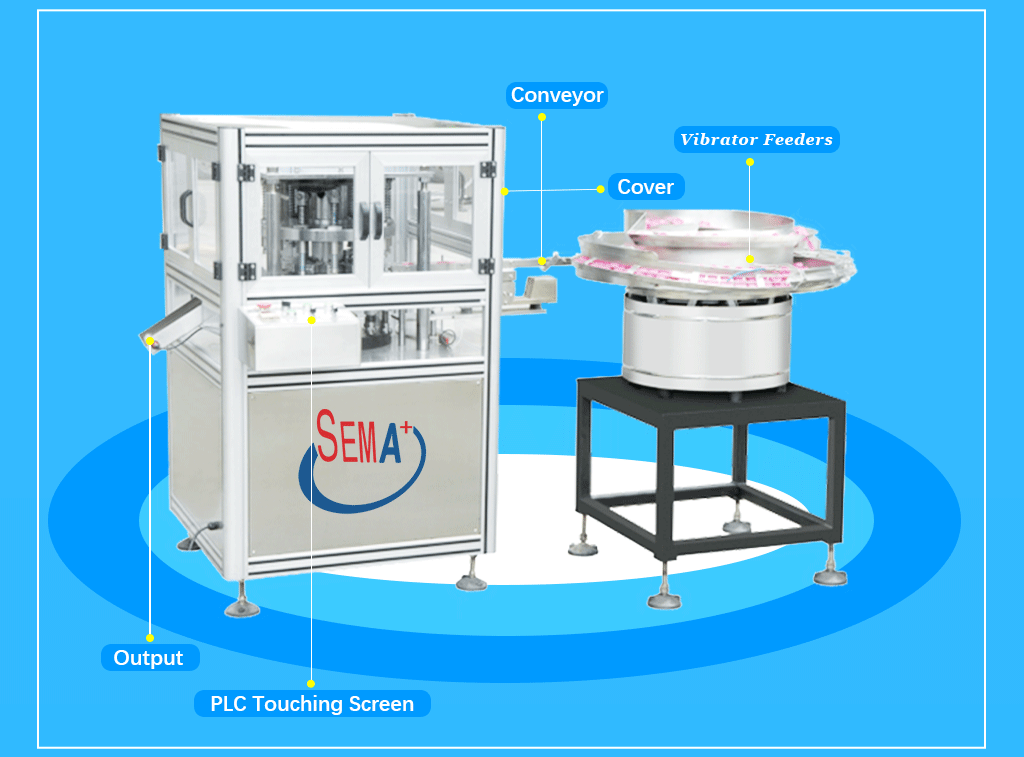

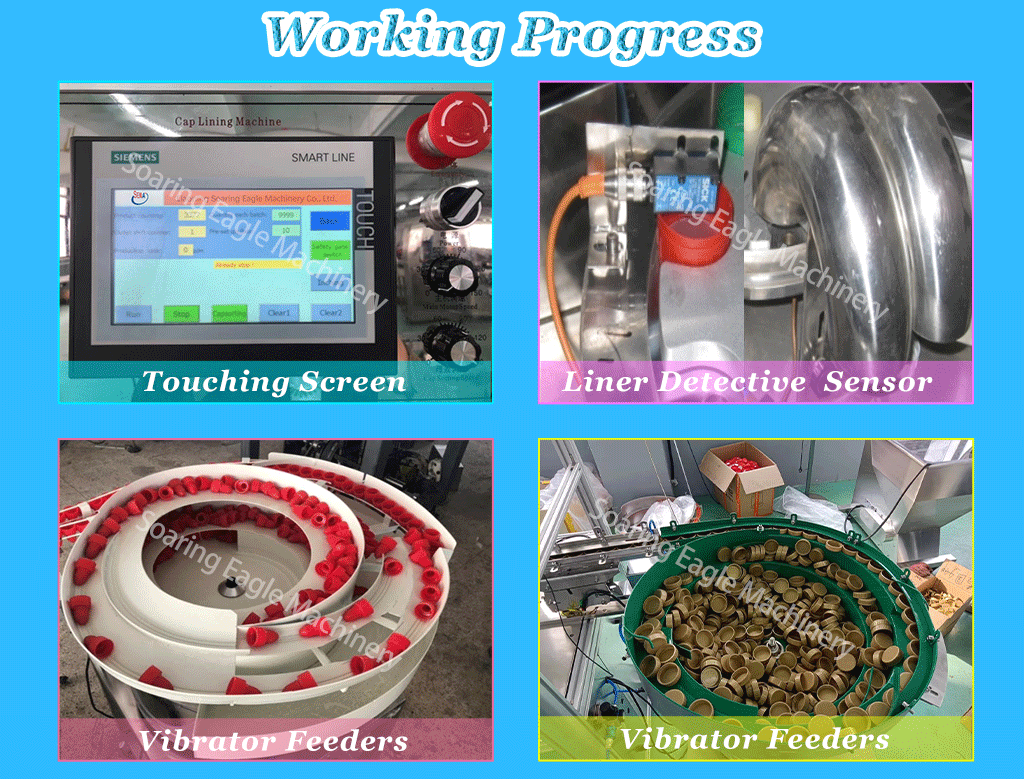

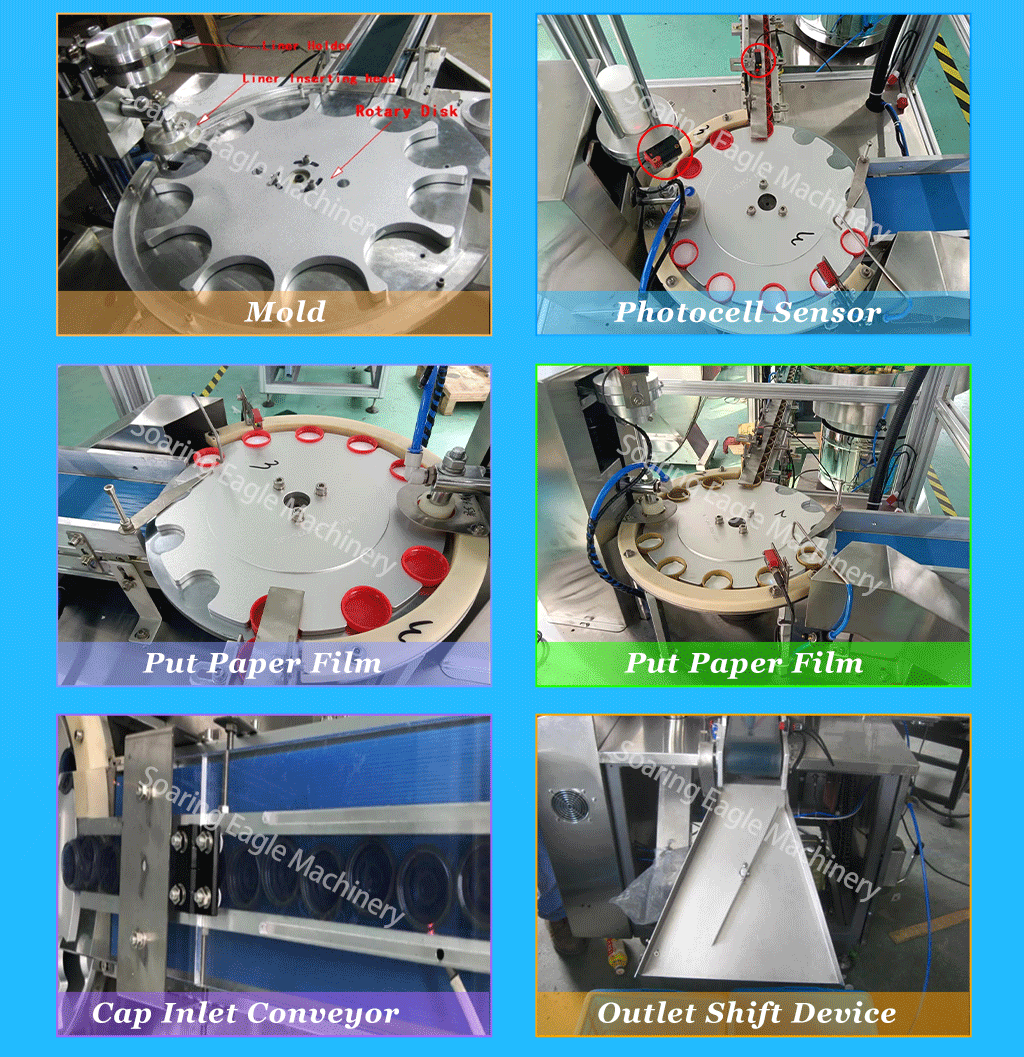

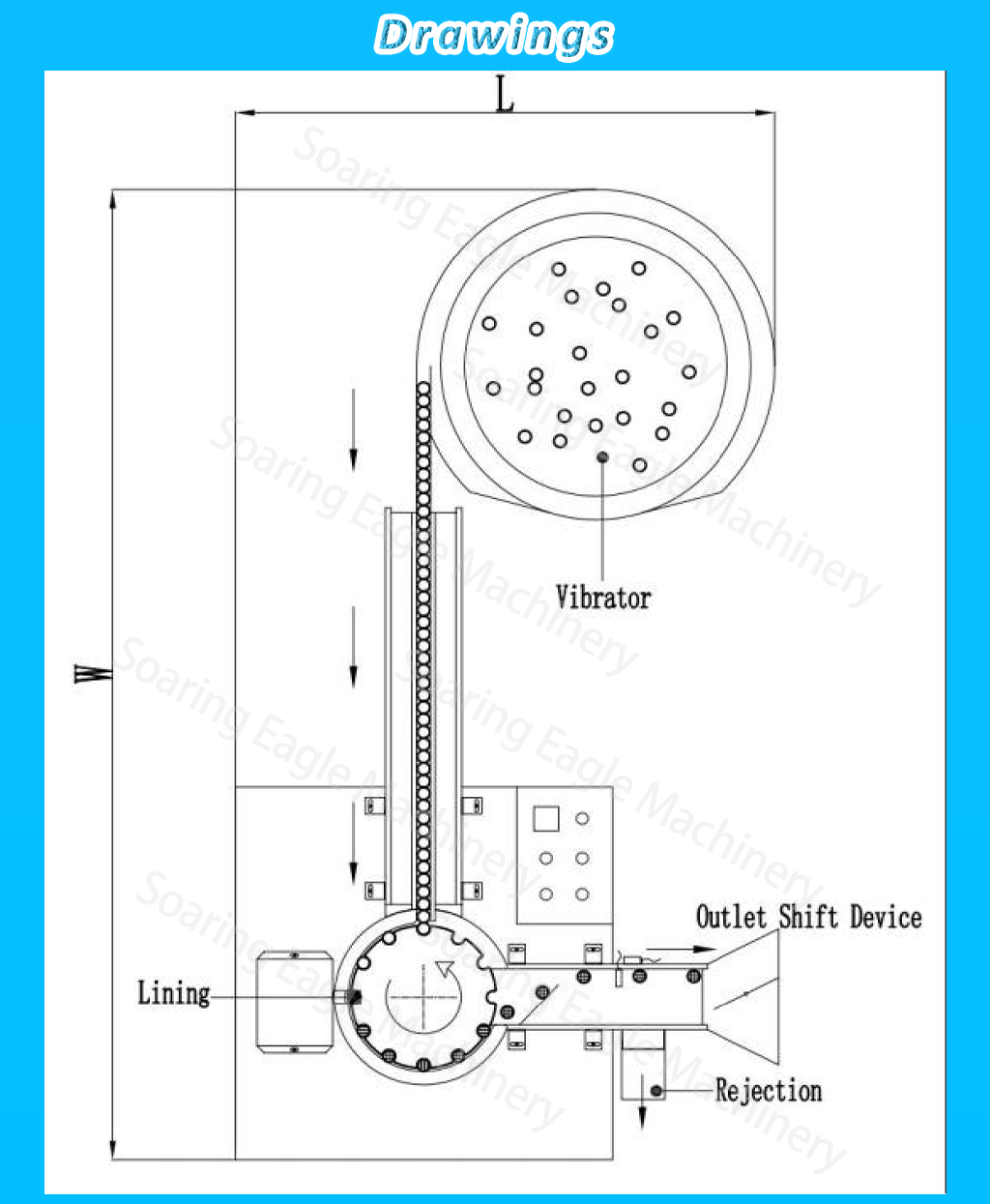

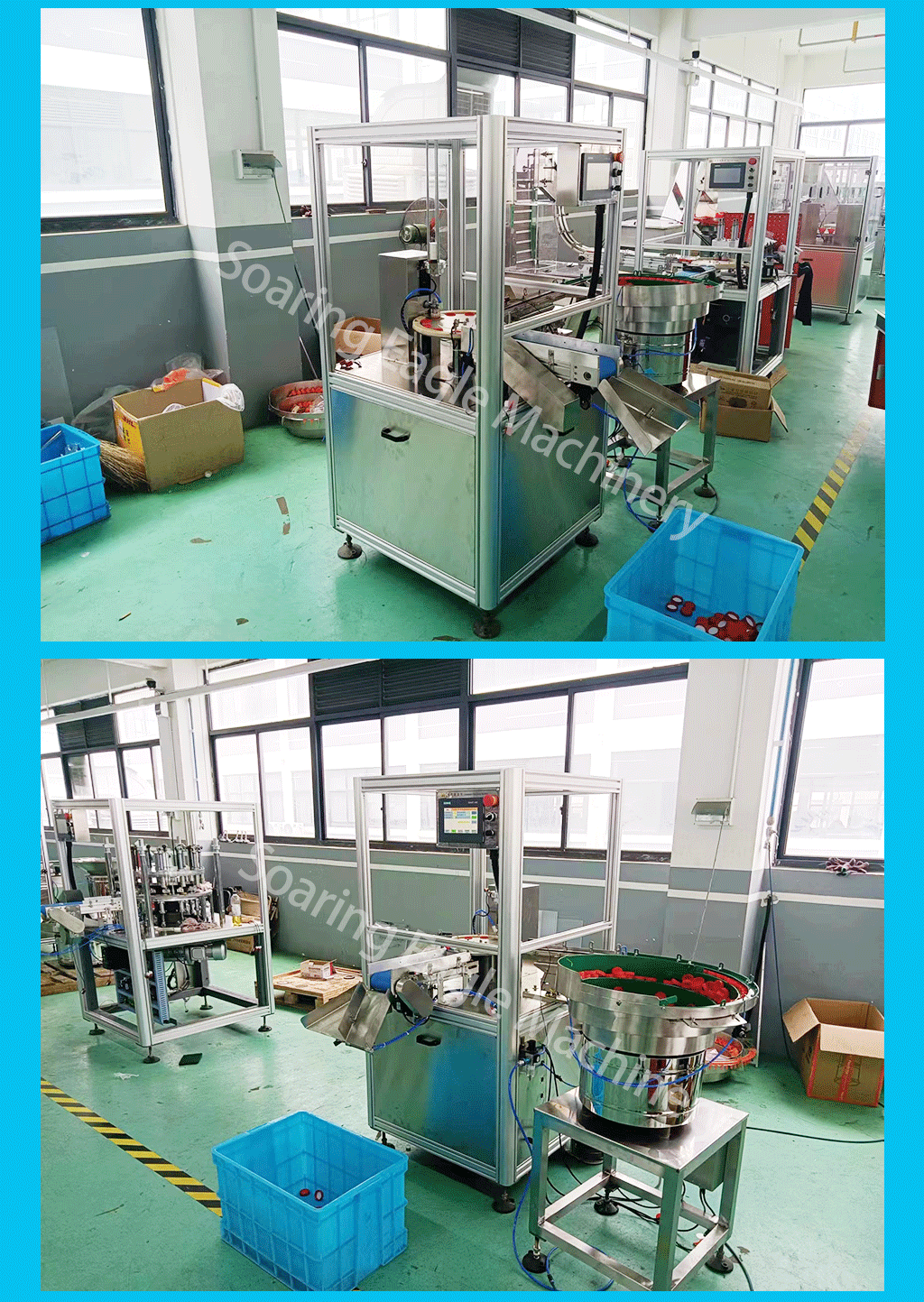

2. Structural Composition of the Machine:

Automatic Vibrator cap feeder for sorting and feeding disordered caps into the upwards -conveyor feeding caps into indexing plate-Hot melt glue machine dropping glue inside caps(optional)--vacuum suction and liner inserting into caps---Detective and counting caps.

3.Outlet shift device and no liner caps rejection sensors are optional in the machine.

4.Machine capacity:80 PCS/Min

5.G/N Weight: 600/500 KGS.

6.Power: 1.8 KW, 220V.single Phase or 380 V,3 phases,50/60 HZ.

Specifications:

| Model : | Twist cap wadding capping lining machine |

| Specification of aluminium foil : | 20-50mm |

| Capacity : | 80pcs/min |

| Powder Supply : | 220V 50Hz |

| Machine Size : | 3000*1000*1500mm |

| Machine weight : | 500kgs |

Our friendly team would love to hear from you!