Description:

The equipment is suitable for emulsification of the pharmaceutical. Cosmetic, fine chemical products, especially the material having high matrix viscosity and solid content. Such as cosmetic, cream, ointment, detergent, salad, sauce,lotion,shampoo, toothpaste and so on. The emulsifier is through the high-speed rotation of the homogenizing head connected to the engine, so that the material will become more delicate, and promote the fusion of oil and water.

Structure:

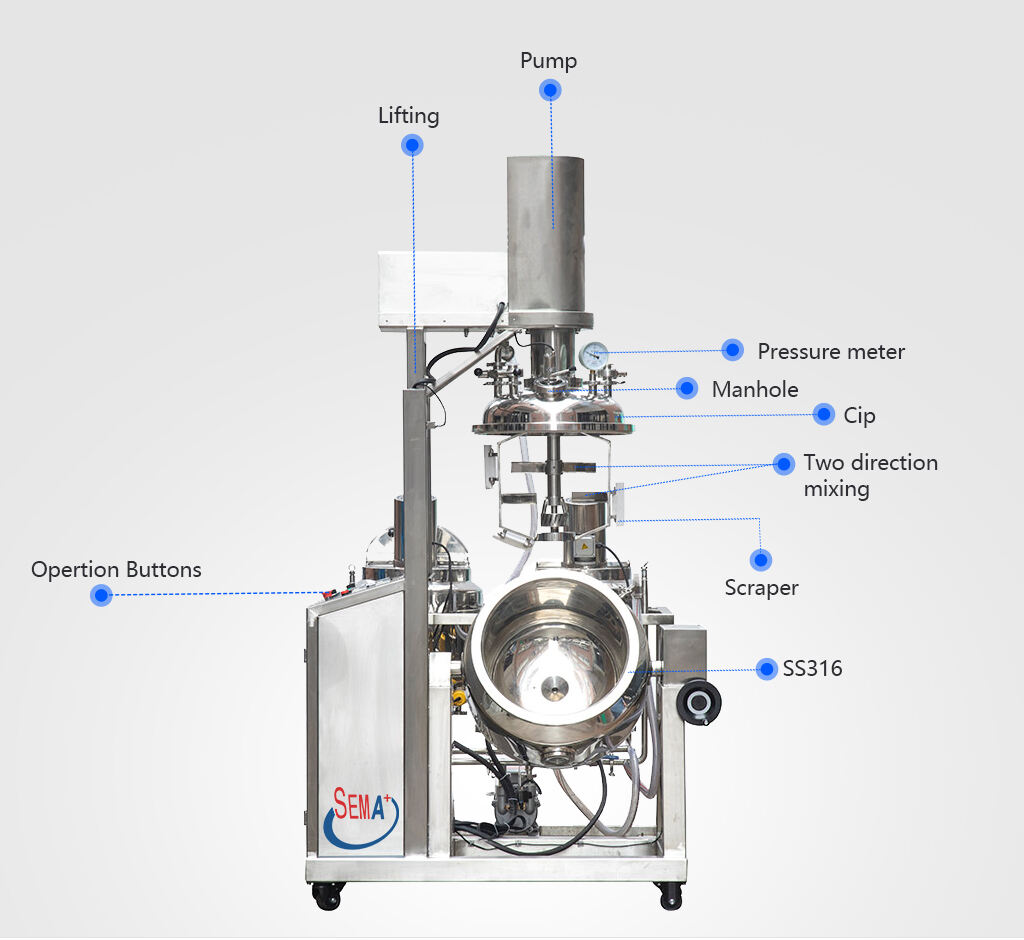

including main emulsifying pot, water and oil pot, vacuum pump, mixer, emulsify mixer, temperature control system. Safety system work frame and so on.

Depends on customer different requirements, we have different sizes emulsification machine.

Specifications:

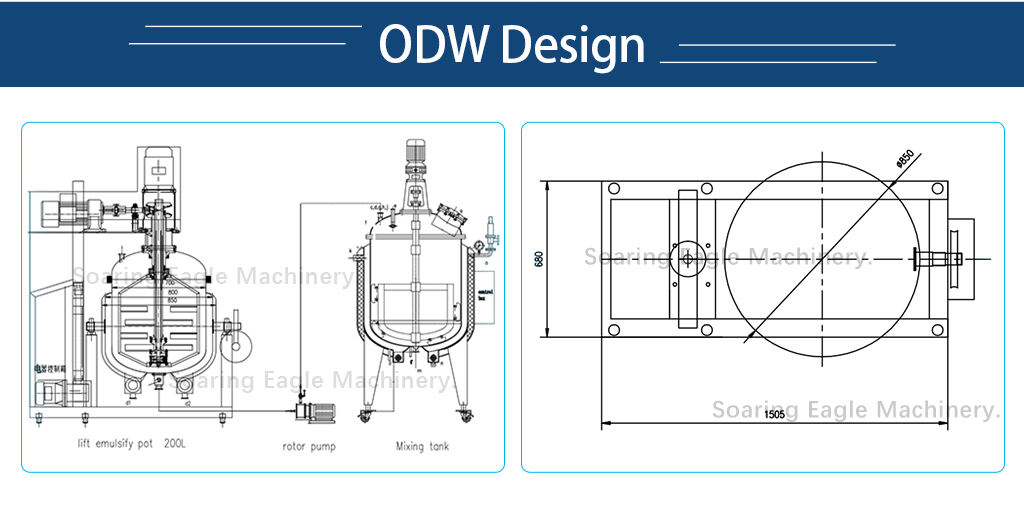

| Main Mixing tank: | Total Volume:250L | Working volume:200L |

| Pressure:-0.1Mpa in pot 0.1Mpa in jacket | ||

| Temperature:≤100℃ | ||

| low speed agitator: | speed:0—60(R/min) | power:1.5KW |

| homogenizer: | speed:0-2800(R/min) | power:4KW |

| vacuum degree:-0.09(Mpa) | ||

| Vacuum pump: | format: round | Power:1.5 KW |

| Scraper tank | Dimension (mm):700(900)×650mm(total length 2250mm) | |

| Work volume L:300 | 1. Structure: vertical three-layer, fully sealed straight cylinder upper and lower head, support foot installation, flangeconnection. Mechanical mixing on the tank top.2. Surface treatment: the inter | |

| Inside pressure MPa:Air pre | Jacket pressure MPa:<0.1 | |

| Jacket temperature ℃:115 | Inside temperature ℃:100 | |

| Heat area m2:1.8 | Motor power KW:1.5 | |

| Mixer speed R.P.M:88 | Heat power :18KW | |

Our friendly team would love to hear from you!